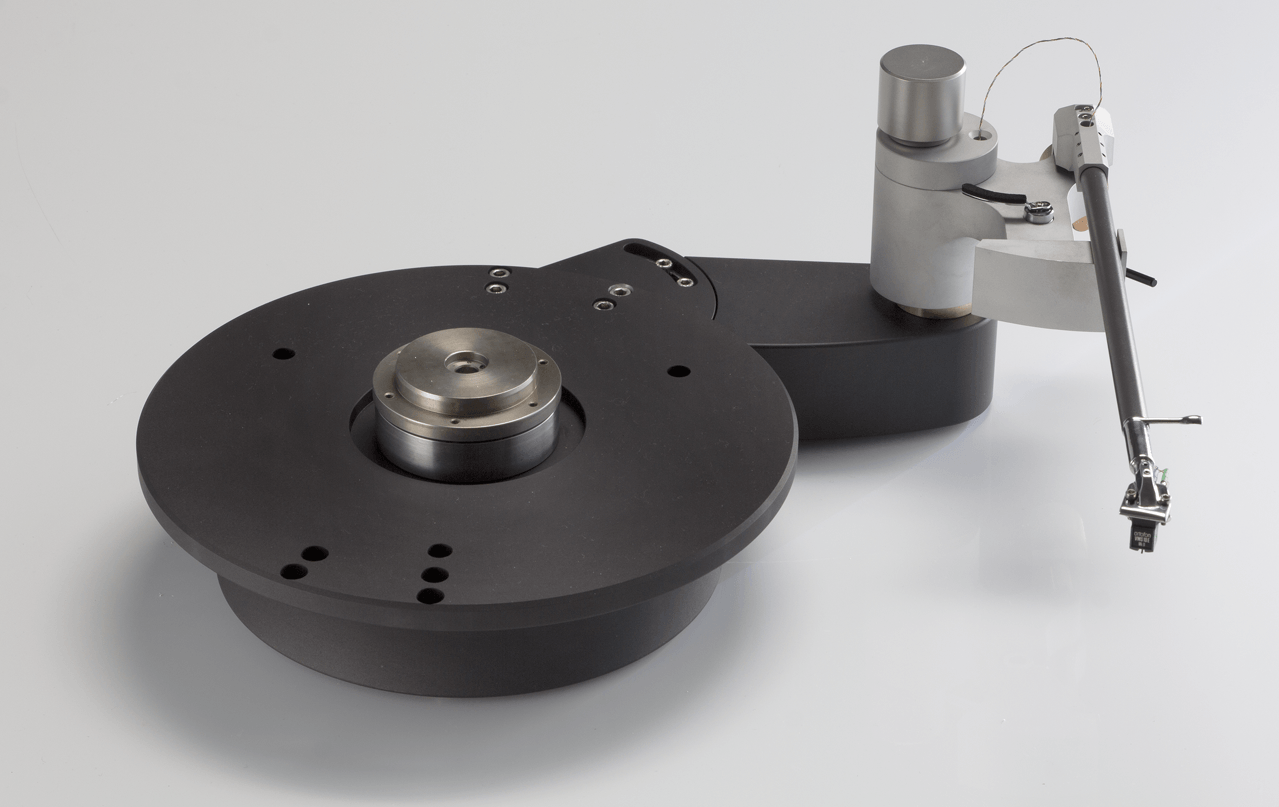

recordplayer TM1 details

The TM1 is a new type of vibration-damping solid recordplayer and standalone solution. This offers optimal conditions for sound reproduction quality. And it is particularly constant because the turntable is an acoustical solid on a table that, due to its weight and its elastically mounted spring dampers, looks like a subchassis acts and thus eliminating disturbing movements from the substrate.

The TM1 is uniquely calm in the sound. Described pictorially, it has a high resolution on a deep black background. This benefits the listener through relaxed and enjoyable listening to music. Developed by Dipl. Ing. Engineer Ralf Wölfel, who completely rethought the physics of sound reproduction. The technology behind it: Each individual component is optimized to the limit of what is technically feasible to avoid disruptive

oscillations. A turntable cannot do more.

- The puristic design of the TM1 conceals its technically complex inner workings in an unobtrusive, lightweight manner.

- Pleasant haptics through ergonomic shapes and matte surfaces.

Audiophile sound sculpture

The back wall is equipped with various options for mounting devices, such as the phono preamplifier, on the back. The motor control and power supply of the turntable are also invisibly attached to the rear wall. The front panel of the device shows on the side cheeks. Thus, the switches can be conveniently operated. We want to achieve with it that only a minimum of devices is to be seen with the view.

Overall, it was important to us in this model that the turntable can play quietly, regardless of vibrations from the substrate, and thus provide optimal conditions for playing the record. On the other hand, we want to highlight the turntable as an audiophile sound sculpture.

Stiff & damped = sound optmized

The platter is the heart of this turntable. We have combined six solid layers consisting of Corian®, aluminum and graphite in a sophisticated way. The result: an extremely rigid and ultra-damped unit. Disturbing finest vibrations are prevented. An effect that has a noticeably positive impact on the sound image.

Easy balancing

The platter can easily be brought into balance by adjusting the spikes located on the lower pot. These are adjusted through the platter with the supplied hexagonal pin wrench.

Stabilizing & calm running

The platter bearing is a patented one Ars Machinae new development. It cleverly combines the advantages of various common bearing variants. It is so user-friendly.

The technology behind: Despite its upper position, the bearing ball is in permanent contact with oil. So that's the turntable optimally stabilized and at the same time smooth running and wear-free. Thus, the turntable bearing contributes to a perfect music reproduction quality.

Damping & electrically conductive

The platter overlayer consists of an 0,31 inch thick graphite plate and together with the record clamp forms a unit that optimally holds the record presses and smooth running for the cartridge. Due to its slightly concave shape, it forms a good connection with the clamp.

Note: We also offer this combination for other turntables as a set.

Good record handling

The platter overlayer allows for a good handle of the vinyl because you can easily reach under the edge of the record.

High precision manufacture

High-quality use of materials: The individual components are made of solid blocks of aluminum and bronze. Uncompromising materials of the highest quality, purity and environmental compatibility are used. Manufactured in Germany by our regional partners working for precision engineering on highly sensitive and precise CNC milling machines or CNC lathes.

Clamp with damper

The record weight (clamp) is patented with an innovative cushioning system equipped in cooperation with the University of Bayreuth and the Fraunhofer Institute was developed by us. The combination of weight and cushioning ensure a detailed and high-resolution sound reproduction. It weighs 22,93 oz and thus very efficiently presses the record onto the platter. The ergonomic shape enables a pleasant feel, which many of our customers notice positively again and again.

> We also offer our plate weight ARS M1 individually.

Analog drive

The turntable drive by means of straps works according to the highest technical and audiophile standards. The operation of the motor generator is purely analog. Any kind of quartz generators and digital frequency dividers are deliberately avoided. The speed is adjustable to 33 1/3 and 45 rpm.

Damped rigid tonearm

Our tonearm Lignum R was optically and functionally developed by us especially for the TM1/M1: The 12.2 inches tonearm tube made of a wood-carbon combination ensures effective damping and high rigidity. In this way, disruptive vibrations are effectively suppressed and the sound reproduction quality increased.

Note: We also offer our tonearm separately for other turntable models.

Choosing two different geometries

In the first step with offset angle to Baerwald or one rigid straight lead (Zero degrees). This selection offers additional possibilities for audiophile experiments.

In the second step the stabilization of the tonearm bearing is then adjusted to match the selected offset angle on the bearing housing.

In the third step, the overhang/underhang must also be adjusted with the center distance adjustment function (pivot to spindle distance) to match the selected tonearm geometry.

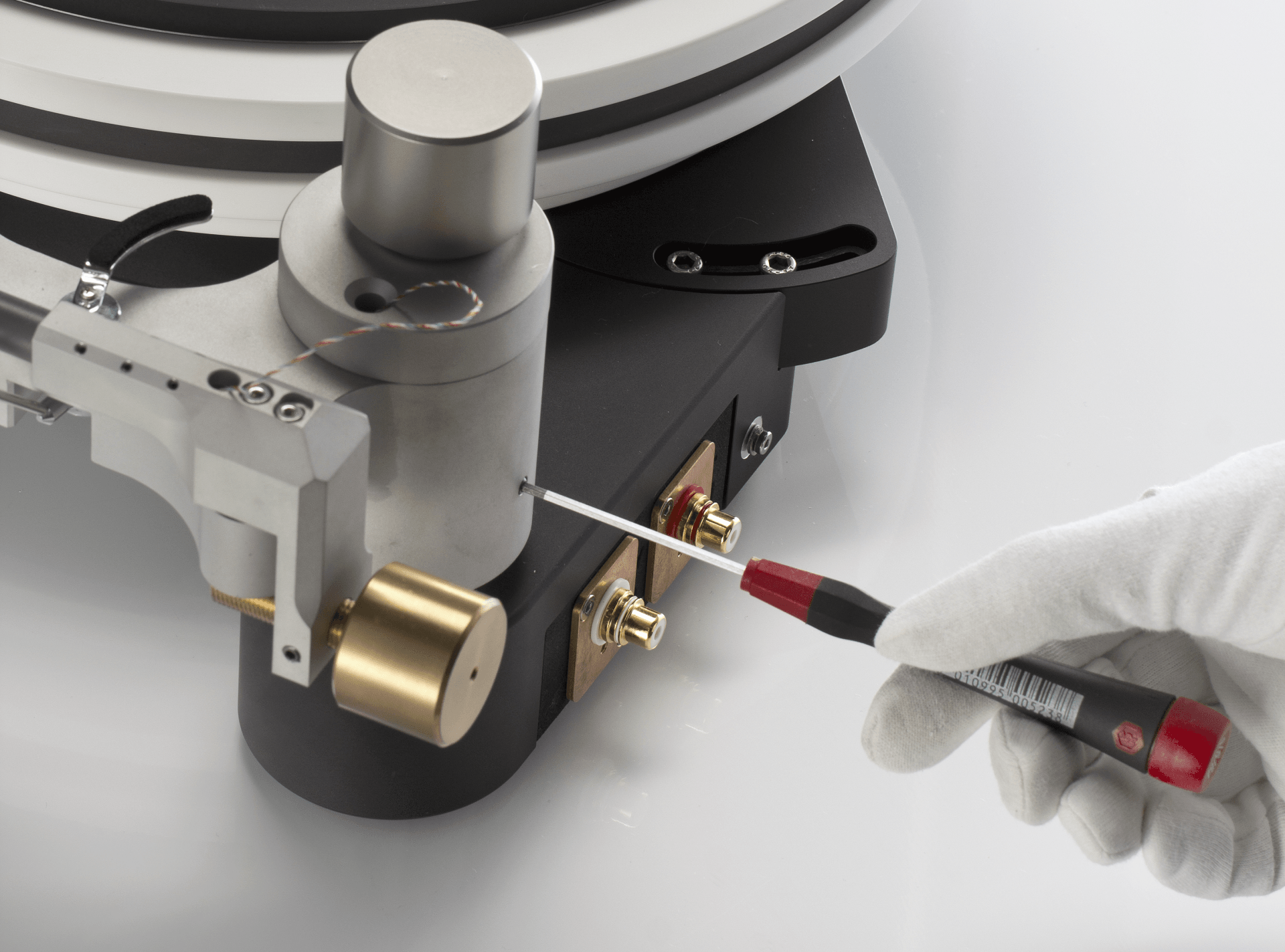

Easy adjustment of the tonearm bearing stabilization

On the bearing housing of the tonearm, the bearing stabilization set to match the selected offset angle. This is done by adjusting the screw in the slot.

We have stabilized the one-point bearing of our tonearm because it makes it easier to use when placing it on the record. This is how we eliminate the usual "annoying wobbling of typical one-pointers". In addition, we have installed this stabilization for both tonearm geometries.

It doesn't matter whether you operate the tonearm straight or with an offset - it is always stabilized.

Stiffened head shell

The head shell can be removed without an additional cable separation point and is extremely rigid. This measure avoids unnecessary disruptive factors that could affect the sound. At the same time, the cartridge can be conveniently installed. Especially if it doesn't have threads.

For assembly, the head shell is simply placed on the sleeve and fixed with the two threaded pins on top.

The handling aid is located at the back of the sleeve. We want to avoid interfering signals and have therefore placed the position as far away from the cantilever as possible.

Easy azimuth adjustment

The grub screws at the top of the headshell have another purpose: they are used to adjust the azimuth. The headshell is straight at the front edge, aligned horizontally. This provides visual orientation while adjusting the cartridge/ stylus tip in the right position.

Tip: If the voices are not in the middle during the listening test, you can adjust this using the azimuth.

Setting the distance P2S

Horizontal tonearm geometry: The entire tonearm base is swiveled to adjust the center distance.

This is needed for the adjustment of the tonearm geometry (pivot to spindle distance / change between overhang and underhang).

Precise adjustment of the counterweight

The vertical tracking force is adjusted on the counterweight. Made of solid bronze, its fine thread allows precise adjustment while the cantilever is located on the tonearm scale. One turn is equivalent to 0,04 lbs of setting.

Skating / anti-skating: We deliberately do without an anti-skating device. Because this is an oscillating system. That's why we chose one 12.2 inches long tonearm. According to our calculations, this measure is the optimal ratio of a good fit and a moderate horizontal skating force. So our tonearm gets along without anti-skating.

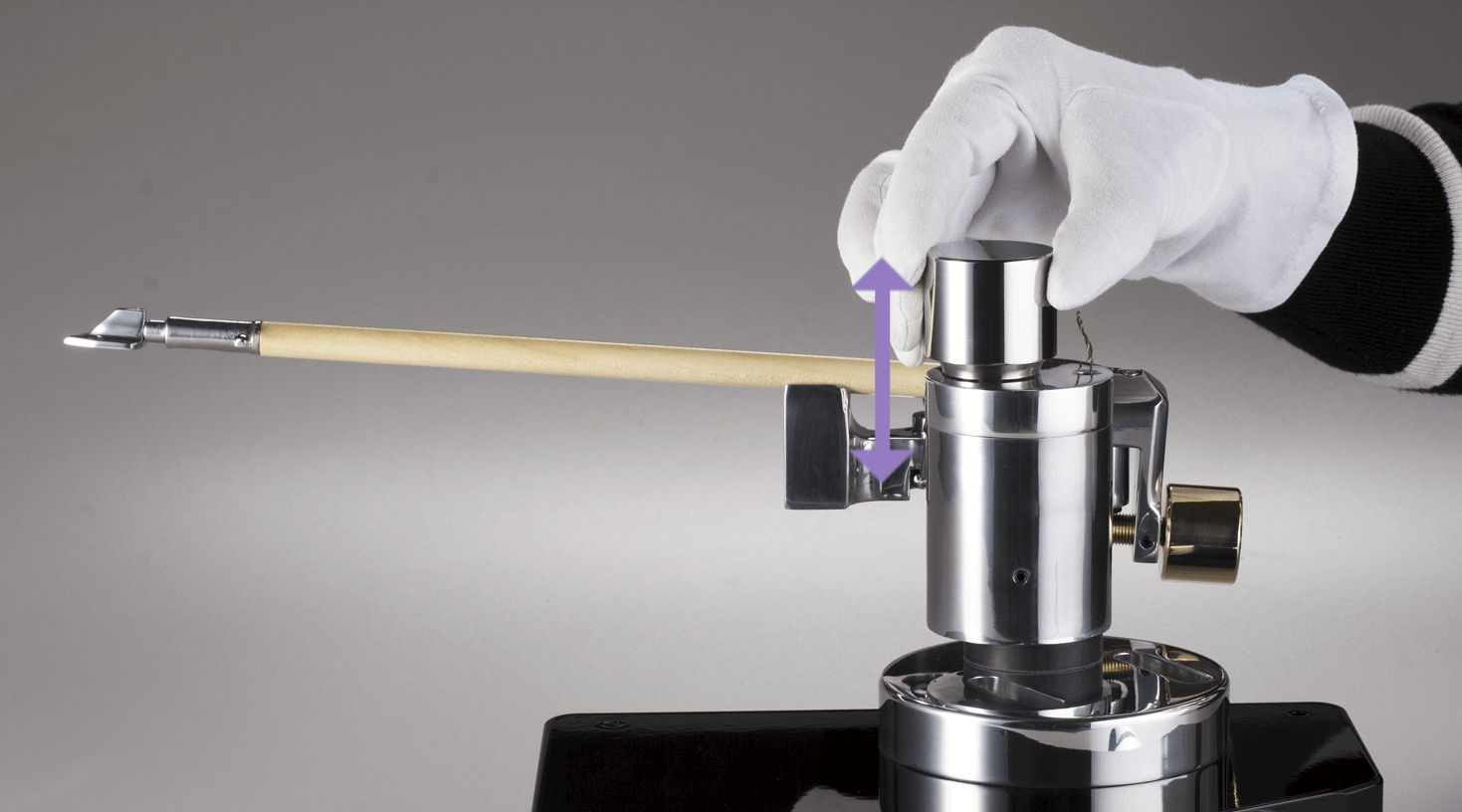

VTA fine adjustment during playback

Setting the vertical tracking angle: With the top knob, the height adjustment can be adjusted conveniently. Also during playback. Use your hearing for this. This allows you to further optimize the sound.

Prevent vibrations

When the VTA is set, the position can be fixed using a clamp pin. We recommend this measure because it also serves to avoid spurious vibrations.

Some more data...

- Platter weight: 17,64 lbs, turntable weight: 52,91 lbs. chassis weight: about 176,37 lbs.

- Dimensions: External dimensions/space requirement: w= 39,37 in, d= 23,62 in, h= 39,37 in.

- The TM1 is exclusive manufactured in our manufactory in Lichtenfels, Franconia (Germany). We have our individual parts produced by regional specialist companies. They are carefully quality checked and processed by us. Then we assemble the unit in our company. Each product is carefully inspected and tested by us before it leaves. The turntable is carefully packed in a flightcase. So that he has a safe transport. And equipped with several tools for mounting, as well as a detailed instruction manual. The chassis must be well packed and placed on a pallet.

- We offer one guarantee 10 year warranty on all mechanical parts and a lifetime warranty for service. We ensure that your M1 retains its value. We are here for you if you have any questions. The M1 is a masterpiece of German engineering and something very unique and exclusive.